Introduction To The Use Of CNG Gas Systems for Vehicles

1. Introduction to CNG Supply System

The CNG supply system is an additional device that uses compressed natural gas (CNG) as the combustion material on the basis of the original prototype vehicle's single fuel supply system. After installation, the power performance of the vehicle is reduced by no more than 5%, and the emissions are far better than the limits of Euro II standards (reaching Euro III standards). Moreover, the driving characteristics of the vehicle after installation are no different from before installation.

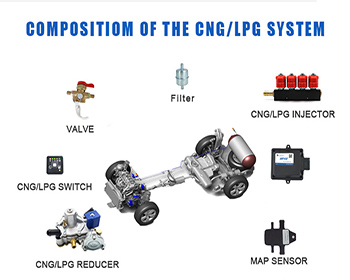

2. System composition

The CNG supply system consists of three parts: gas storage and supply, pressure reduction, and control:

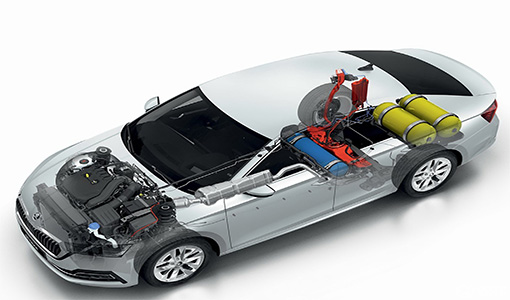

(1) Gas storage and supply section

The gas storage and supply section refers to the device that stores CNG, mainly composed of gas cylinders, high-pressure solenoid valves, pressure gauges, gas nozzles, and high-pressure pipelines.

(2) Decompression section

The pressure reduction section refers to a series of devices that reduce compressed natural gas (CNG) to a pressure suitable for engine operation and provide CNG to the engine for combustion through a series of devices, mainly composed of a pressure reducer and low-pressure pipelines.

(3) Control section

The control part refers to a device that can switch fuel at any time according to user needs and adjust the CNG supply amount according to engine operating conditions. It mainly consists of a conversion switch, ECU electronic control unit, fuel and CNG solenoid valves, injection valve common rail, and related wiring harnesses.

3. System performance characteristics

(1) The production and installation of the entire system comply with the QC/T247-1998 standard;

(2) The entire system is composed of sub assemblies, and each assembly undergoes sub assembly inspection at the factory for easy installation and inspection of the entire vehicle;

(3) The entire system has been equipped with safety devices in multiple locations, improving the safety and reliability of the entire vehicle operation;

(4) The system is easy to operate, easy to maintain, and has good interchangeability;

(5) The system is a daily maintenance free product.

4. Structure and function of the main components of the gas supply system

(1) High pressure gas cylinder

Compressed natural gas cylinders for automobiles are designed, manufactured, and accepted in accordance with GB17258, and are required to be filled with natural gas that meets the gas quality standards of GB18047-2001 Compressed Natural Gas for Vehicles.

(2) Spray valve and common rail

The number of gas nozzles is equivalent to the number of engine cylinders, installed inside the gas nozzle guide rail. CNG (gaseous) flows through a pressure reducer to the gas guide rail and reaches the gas nozzle. Gas enters the engine through the engine intake pipe through the nozzle, and the opening and closing of the gas nozzle are controlled by the ECU electronic control unit.

(3) Pressure reducer

The pressure reducer has functions such as pressure reduction, pressure balancing, heating, and gas supply regulation. The pressure reducer is a key component of the gas supply system. It consists of a pressure reducing valve, solenoid valve, idle adjustment device, etc. The pressure reduction process of CNG is an endothermic process, so the pressure reducer is equipped with a water channel heated by the engine's circulating water.

(4) ECU electronic control unit

The ECU electronic control unit has self diagnosis and adaptive functions. After monitoring the working condition of the engine, it provides a suitable fuel supply device according to the driving requirements of the vehicle. Its working temperature is -40 ¡æ -100 ¡æ, and it can be programmed on a PC.

(5) Conversion switch

The main function of the conversion switch is to perform oil and gas conversion, display gas volume, and select the starting method.

5. Installation and commissioning of gas supply system

The installation of the gas supply system should strictly follow the QC/T245-1998 standard; The system is generally free of debugging after leaving the factory.

6. Precautions for the use of gas supply systems

(1) Driver's Operations

Drivers of dual fuel vehicles must participate in CNG vehicle driving technology training.

(2) Routine inspection before departure

* Check the inflation volume: Connect the entire vehicle power supply, turn on the ignition switch, press the oil gas switch to the "gas" position, and check the air volume displayed on the air volume display.

* Check sealing: In addition to conducting regular inspections before departure, it is also necessary to check for leaks in the CNG supply system's gas supply pipeline and connector components; And smell for any odor (natural gas has been odorized).

(3) Engine start

Start with CNG: Place the oil gas switch in the "gas" position and follow the general operating procedure to start the car with CNG. When starting, the engine water temperature should be above 60 ¡æ, and low gear is preferred.

Start with gasoline: Press the switch to the "oil" position to start according to the general operating procedure.

(4) Fuel conversion during driving

It is recommended to use the same fuel for driving after starting. During fuel conversion, there will be a transition period of fuel supply, during which the engine will experience a decrease in speed or a slight pause. So if fuel conversion is carried out while driving, it should not be done in areas with congested traffic, uphill and downhill roads, turns, or poor visibility. The specific operational requirements are as follows:

* Oil ¡ú Gas: Press the toggle switch to the "gas" position.

* Gas ¡ú Oil: Press the switch to the "oil" position.

(5) Precautions for Drivers

a. Strictly follow the driving safety regulations while driving, fully estimate the road conditions and conditions, in order to avoid accidents when passing or passing.

b. When parking a dual fuel vehicle, it is advisable to choose a cool and ventilated place to prevent exposure to sunlight, and keep it away from sources of fire and heat.

c. If a dual fuel vehicle discovers a natural gas leak while driving, it should immediately pull over, close the natural gas storage cylinder valve, and let the natural gas in the pipeline run out; Then use gasoline to drive the car to the assembly plant for treatment, and only after the leakage is eliminated can natural gas continue to be used for driving.

d. If a fire occurs while driving, the power supply and natural gas storage cylinder valve should be quickly turned off, the fire source should be isolated, and a fire extinguisher should be used immediately to extinguish the fire. In addition, on-site personnel should be quickly evacuated to a safe place (in an upwind direction). Open flames are strictly prohibited on site when discharging high-pressure natural gas.

e. For long-term use of natural gas in automobiles, it is recommended to burn for 1-2 hours every 500km to 1000km to prevent fuel supply system failure.

Refer to£ºhttps://afdc.energy.gov/vehicles/how-do-natural-gas-cars-work

Refer to£ºhttps://afdc.energy.gov/vehicles/how-do-natural-gas-cars-work

The pictures and articles are from the internet. If there is any infringement, please contact us to delete them.

Popular articles

-

Advantages Of CNG Gas V

Compressed natural gas vehicles are vehicles th

-

How the CNG Automotive S

Compressed natural gas (CNG) automotive systems

-

What Is CNG Pressure Red

The pressure reducer of natural gas vehicle is

-

Advantages And Principle

LPG and CNG are two mainstream alternati

-

Differences Between Sing

Characteristics of Gas Single Point Device

-

Reasons For High Gas Con

1. Original vehicle condition A. The tec

-

How To Improve The Power

1. Install ignition advance angle What i

-

How The CNG Gas Vehicle

If you want to know ¨C how does the CNG conversi

Latest comments

0piece comment

no comments, welcome to comment¡£