The advantages and principles of converting automotive oil to gas

1¡ª¡ª Advantages

1. Stable combustion, no detonation, and easy cold and hot start.

2. Compressed natural gas storage, transportation, depressurization, and combustion are all carried out under strict sealing conditions, making it less prone to leakage. In addition, its gas storage cylinder has undergone various special destructive tests, making it safe and reliable.

3. Compressed natural gas combustion is safe, with less carbon deposition, reduced air resistance and detonation, which is beneficial for extending the service life of various engine components, reducing maintenance frequency, and significantly reducing maintenance costs.

4. It can reduce the engine's oil consumption.

5. Compared to gasoline, using compressed natural gas can significantly reduce emissions of carbon monoxide, sulfur dioxide, carbon dioxide, and other pollutants. And there are no carcinogenic or toxic substances such as benzene and lead that pose a threat to human health.

6. The economic benefits are relatively high. Natural gas is easily mixed with air in the engine, with complete and clean combustion, less carbon deposition, good anti explosion performance, and no dilution of lubricating oil. Therefore, it greatly reduces the wear of parts in the engine cylinder, which can extend the life of the engine and the service life of the lubricating oil. The calorific value of one cubic meter of natural gas is equivalent to the calorific value of 1.1 liters of gasoline, and the price of one cubic meter of natural gas is only half of that of gasoline.

7. Good social benefits. Compared with petroleum fuel, gas fuel has less energy loss and less harmful emissions during the preparation process, which is more beneficial for environmental protection.

2¡ª¡ªStructure

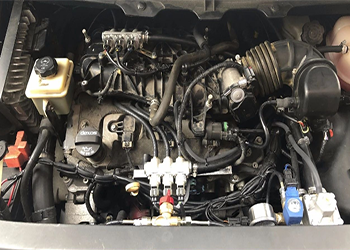

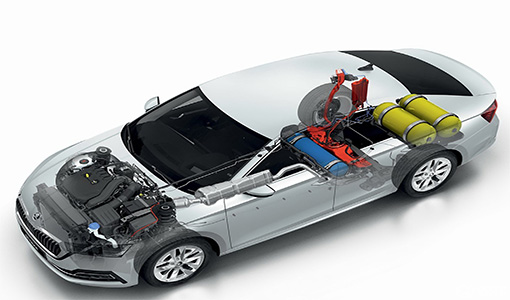

CNG vehicles adopt standardized vehicle modification, adding a set of "vehicle compressed natural gas conversion device" while retaining the original fuel supply system. The modification part consists of the following three systems.

(1) Natural gas system. It mainly consists of an inflation valve, a high-pressure shut-off valve, a natural gas cylinder, a high-pressure pipeline, a high-pressure joint, a pressure gauge, a pressure sensor, and a gas volume display.

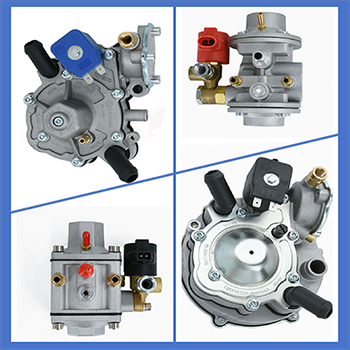

(2) Gas supply system. Mainly composed of gas high-pressure solenoid valve, three-stage combined pressure reducing valve, mixer, etc.

(3) Oil gas fuel conversion system. It mainly consists of a three position oil and gas conversion switch, an ignition time converter, and a gasoline solenoid valve.

There are two safety devices installed at the mouth of the gas cylinder: a fusible plug and a bursting disc. When the temperature of the cylinder exceeds 100 degrees Celsius or the pressure exceeds 26MPa, the safety device will automatically rupture and release the pressure. The pressure reducing valve is equipped with a safety valve; During the installation of gas cylinders and high-pressure pipelines, shock-absorbing rubber pads and clamps are securely fastened. Therefore, this system is the safest and most reliable in use. When a car uses CNG as fuel, natural gas undergoes three-stage pressure reduction and is mixed with air through a mixer before entering the cylinder. The compressed natural gas is reduced from the rated intake pressure to negative pressure, with a vacuum degree of 49-69KPa. The combination of pressure reducing valve and mixer can meet the concentration requirements of mixed gases under different operating conditions of the engine. The pressure reducing valve assembly is equipped with an idle valve to supply idle air to the engine; During the pressure reduction process of the compressor, it needs to expand and do work to absorb heat from the outside. Therefore, there is also a heating device on the pressure reducing valve that utilizes the engine's circulating water; To improve the operational performance of the vehicle, the cab is equipped with an oil gas fuel conversion switch to uniformly control the oil gas solenoid valve and ignition time converter. The ignition time converter automatically converts the different ignition advance angles of the two fuels by the circuit system; The 5 traffic lights on the gas volume display on the dashboard show the storage capacity of the gas cylinder; There is also a gas supply button for the engine on the fuel conversion switch. Therefore, it has complete functions and is very easy to operate. When the fuel switch is placed in the natural gas position, the solenoid valve opens and the gasoline valve closes. The combustion gas in the air storage cylinder flows through the main air valve, filter, and solenoid valve before entering the pressure reducer. After multi-stage pressure reduction to negative pressure, it enters the mixer through the power valve and mixes with the air from the air filter to ignite and drive the engine crankshaft to rotate. The mixer can automatically adjust the air supply and evenly mix air and natural gas according to the different vacuum levels generated by the engine under different operating conditions under the regulation of the pressure reducer, to meet the fuel supply requirements of the engine. The power valve can change the low-pressure pipe and cross-sectional area of natural gas, adjust the closing of the mixing valve, restore the original vehicle fuel supply system to normal fuel supply, and ensure the normal operation of the engine. The control system mainly consists of fuel conversion switches, which control the opening and closing of gasoline solenoid valves and gas solenoid valves to achieve fuel and gas supply selection.

In summary, as long as the installation of gas systems is carried out in accordance with national requirements at regular manufacturers, the installation process and quality can be guaranteed, and the safety of CNG vehicles is beyond doubt.

Refer to:https://www.bglgas.com/cng-advantages/

The pictures and articles are from the internet. If there is any infringement, please contact us to delete them.

Popular articles

-

How the CNG Automotive S

Compressed natural gas (CNG) automotive systems

-

Advantages Of CNG Gas V

Compressed natural gas vehicles are vehicles th

-

What Is CNG Pressure Red

The pressure reducer of natural gas vehicle is

-

Advantages And Principle

LPG and CNG are two mainstream alternati

-

Reasons For High Gas Con

1. Original vehicle condition A. The tec

-

How To Improve The Power

1. Install ignition advance angle What i

-

Differences Between Sing

Characteristics of Gas Single Point Device

-

How The CNG Gas Vehicle

If you want to know ¨C how does the CNG conversi

Latest comments

0piece comment

no comments, welcome to comment¡£