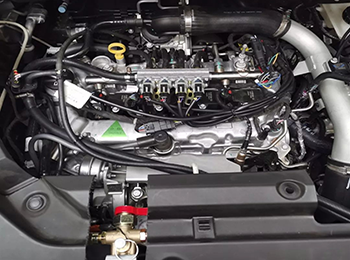

Troubleshooting and maintenance of unstable idle of dual fuel vehicles

Fault phenomenon one: In the use of dual fuel vehicles, sometimes when the vehicle is parked at idle speed, stepping on the accelerator pedal causes uneven engine acceleration, and the speed fluctuates between high and low, commonly known as unstable idle speed. If this phenomenon is not eliminated in a timely manner, it will affect the performance of the vehicle.

Reason and analysis: In general, there are three main reasons for unstable idle speed: first, the intake sensor is not sensitive; Secondly, the intake port of the idle motor is obstructed; The third issue is the imbalance in the mixing ratio of natural gas and air. Dual fuel vehicles can use gasoline or natural gas as engine fuel separately. Regardless of whether they use oil or gas, they share the same idle motor. To ensure the normal operation of the idle motor, it is necessary to ensure that the engine fuel is supplied at a constant speed, otherwise the engine speed may fluctuate. The reason for uneven fuel supply may be due to foreign objects at the inlet of the idle motor, which hinder the normal entry of fuel and prevent the combustion value in the cylinder from meeting the working requirements; If natural gas is used, abnormal curve mixing ratio of the nozzle will also affect the gas supply and idle motor speed; The intake sensor can sense the intake performance of the mixed gas and transmit the detected parameters to the computer control box for analysis and control. If there is dirt on the sensor, it will affect the sensitivity of the sensor, transmit inaccurate information to the computer control box, cause intake control deviation, and result in unstable speed.

Inspection method: Use observation to check for oil stains, carbon debris, and other foreign objects at the inlet of the intake sensor and idle motor. The determination of the phenomenon of mixing ratio imbalance should be carried out through specialized detection software, comparing the gas mixing ratio curve with the benchmark curve to see if they meet the specified requirements.

Troubleshooting method: When the vehicle malfunctions, maintenance should be carried out according to the principle of oil first and then gas, from simple to complex, and from outside to inside. Set the idle dual fuel vehicle to the "fuel" gear first, slowly step on the accelerator with your foot, observe the machine speed, and if there is any abnormality, disassemble the relevant components locally. Use appropriate tools to clean the foreign objects in the air intake to ensure smooth and unobstructed oil and air intake. If there are no abnormalities, it indicates that the fuel system is working properly. The curve mixing ratio and sensor performance when using natural gas should be checked.

When diagnosing gas system faults, the idle dual fuel vehicle should be set to the "gas" gear, a dedicated detection computer should be taken, and the computer should be connected to the vehicle control box with a data cable. Adjust the vehicle condition and check the mixture ratio curve on the computer screen. If there are any abnormalities, adjust it to normal. If it cannot be debugged properly, check the intake sensor again. The main reason for the insensitivity of sensors is the coverage of foreign objects such as oil stains and carbon ash, which leads to a decrease in detection performance. During maintenance, the vehicle should be turned off and the intake sensor should be removed to check for dirt or performance. The sensor should be cleaned of dirt and debris. In general, the sensor itself cannot be repaired in the station area, and can be replaced and eliminated directly.

Preventive measures: In the use of dual fuel vehicles, it is necessary to regularly check the intake port and idle motor for oil stains, clean and maintain them regularly, which can effectively reduce the frequency of such faults.

Fault phenomenon 2: In the use of dual fuel vehicles, sometimes the accelerator pedal is pressed and the vehicle cannot move, or the vehicle runs vigorously but the gas consumption per hundred kilometers increases significantly. If this phenomenon is not eliminated in a timely manner, it will cause economic losses to car owners.

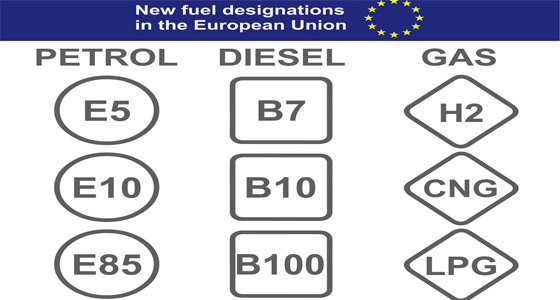

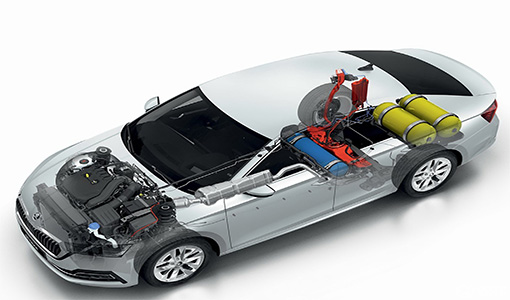

Reason and analysis: In general, the possible causes of gas consumption in dual fuel vehicles are related to abnormal pressure regulator pressure, curve mixing ratio, spark plug and original valve clearance. When operating a dual fuel vehicle, the compressed natural gas in the high-pressure storage cylinder must be depressurized by a pressure reducer before entering the cylinder to form a mixed fuel with air. The combustion of the mixed gas does work to drive the piston movement. The vehicle has strict requirements for the gas mixture ratio in the cylinder, otherwise insufficient combustion or power will occur. Dual fuel modified vehicles use spark plugs in the ignition system of the original gasoline engine for ignition. The compression ratio of the original gasoline engine remains unchanged, and the structure of the original engine remains basically unchanged. The gas mixture ratio can be viewed through dedicated computer software to adjust the mixture ratio curve appropriately. When the gap between the spark plug and the cylinder is appropriate, the spark plug is energized to ignite the mixed gas. If the gap is abnormal, it can also cause gas consumption. When a vehicle experiences gas consumption, targeted inspection and testing should be carried out to clarify the fault phenomenon and related parameters, in order to accurately determine the specific cause and fault location.

Inspection method: To determine the location of fuel consumption faults, specialized computer software is generally used to compare and check for any abnormal phenomena in the gas mixture ratio curve, while also checking whether the pressure parameter values are within the specified range. You can use observation method to check whether there is carbon ash, burn marks, excessive clearance and other conditions in the valve clearance.

Exclusion method: When the vehicle experiences gas consumption, if there are repair conditions, a computer should be used to check the mixture ratio curve during vehicle operation using appropriate computer detection software based on the modification kit used. If the curve is abnormal and the deviation is not significant, it can be adjusted through operation to make the mixture ratio curve consistent with the reference curve. If the mixture ratio curve of the vehicle is normal, you can use a suitable size of "one" to slightly rotate the pressure regulating screw on the pressure reducer, adjust the working pressure of the machine, and adjust the pressure of the pressure reducer to test run. The driver should carefully observe the changes in the vehicle condition based on their feelings and driving experience until the condition is good. If the vehicle cannot be restored to normal operation by adjusting the pressure, the clearance between the spark plug and the original valve should be checked. Due to long-term operation of the vehicle, the spark plug contact gap may change due to vehicle vibration, electric sparks, carbon deposits, and other reasons, which is also a factor affecting gas consumption. The normal spark plug contact gap is 0.8-1 millimeters. In this case, a suitable tool can be used to carefully tap and adjust the gap.

However, there is a certain relationship between valve clearance and the performance of the vehicle model. Some models run for 8000-10000 kilometers, and the valve clearance of the vehicle will automatically decrease. The vehicle is sluggish and consumes gas, and it must be solved by adjusting the valve clearance.

Preventive measures: During the use of vehicles, drivers should have certain knowledge of vehicle maintenance and simple troubleshooting skills, learn to use methods such as observation, smell, cutting, and measurement, timely detect abnormal phenomena such as sound, vibration, smoke exhaust, temperature rise, spark plugs, valve clearances, etc., and do a good job in daily maintenance, repair, and troubleshooting.

Fault phenomenon three: In the use of dual fuel vehicles, some vehicles may experience a lack of power and effort when starting, slow acceleration when running, and inability to reach the desired speed. After shifting to the high-speed gear and reaching a speed of 100 km/h, it becomes difficult to accelerate again. This is a common "power shortage" fault phenomenon in dual fuel vehicles.

Reason and analysis: In general, there are three main reasons for insufficient power: firstly, the imbalance of compressed gas and air mixing ratio; Secondly, the pressure of the pressure reducer decreases; The third issue is nozzle blockage. The proportion of mixed gas entering the cylinder of a dual fuel vehicle engine is controlled by a computer control box to control the injection time. If the mixture ratio exceeds the technical specifications, it will cause gas consumption. If the mixture ratio is too low, the combustion value in the cylinder will decrease, and the energy provided to the vehicle operation will be reduced, resulting in insufficient power.

Inspection method: To determine the location of the "insufficient power" fault, it is generally necessary to use specialized computer software to compare and check whether there are any abnormal phenomena in the gas mixture ratio curve, and at the same time check whether the pressure parameter values are within the specified range. Observation method can be used to check whether the gas nozzle is blocked by carbon ash, oil stains, or foreign objects.

Exclusion method: The computer control box is the core component of the modification kit for dual fuel vehicles, equipped with a computer control program. The mixing ratio curve during vehicle operation can be checked for abnormalities through dedicated computer detection software. If there are abnormalities, they can be adjusted to normal state. When the mixing ratio is normal, if the vehicle shakes or external forces act, it may cause the adjustment screw on the pressure reducer to loosen, resulting in low pressure on the reducer and reducing the amount of air sprayed into the cylinder by the nozzle. The vehicle also exhibits a phenomenon of insufficient power. This fault requires a screwdriver to adjust the pressure adjustment screw on the pressure reducer while observing the vehicle's operation until the vehicle's power is good. During vehicle operation, the nozzle holes of the spray rail may be reduced in diameter due to gas debris adhering to the nozzle wall, resulting in insufficient gas supply and reduced combustion heat value in the cylinder, leading to insufficient vehicle power. To eliminate this phenomenon of malfunction, suitable tools should be used to clean the carbon deposits on the nozzle. Alternatively, gasoline can be used to clean the carbon ash, oil stains, and other dirt on the nozzle, or hole drilling can be performed to increase the amount of gas entering the cylinder block and ensure the normal supply of natural gas.

Preventive measures: In order to effectively prevent the occurrence of faults, it is necessary to take good care of the vehicle, regularly check the condition of the vehicle during use, and maintain it regularly to ensure that the vehicle is always in good health, thereby effectively reducing faults and making it easy to drive.

Refer to:https://energyminute.ca/infographics/natural-gas-vehicles-everything-you-need-to-know/

The pictures and articles are from the internet. If there is any infringement, please contact us to delete them.

Popular articles

-

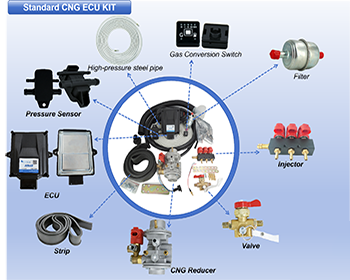

How the CNG Automotive S

Compressed natural gas (CNG) automotive systems

-

What Is CNG Pressure Red

The pressure reducer of natural gas vehicle is

-

Advantages Of CNG Gas V

Compressed natural gas vehicles are vehicles th

-

Reasons For High Gas Con

1. Original vehicle condition A. The tec

-

Differences Between Sing

Characteristics of Gas Single Point Device

-

How To Improve The Power

1. Install ignition advance angle What i

-

Advantages And Principle

LPG and CNG are two mainstream alternati

-

How The CNG Gas Vehicle

If you want to know ¨C how does the CNG conversi

Latest comments

0piece comment

no comments, welcome to comment¡£