Multi valve installation angle

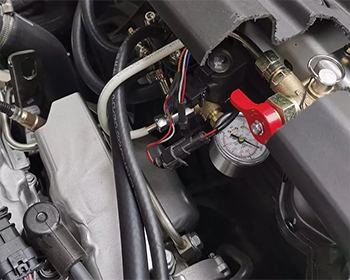

Basic structure and function of combination valve

1. LPG import: During filling, LPG enters the interface of the steel cylinder and is connected to the filling pipeline (D8X1 copper pipe)

2. LPG export: the pipeline interface that supplies LPG to the engine when working with LPG, connected to the gas supply pipeline (D6X1 copper pipe)

3. Imported manual shut-off valve: Manually close the channel for LPG to enter the steel cylinder, and it must be in the open position during filling. Generally, it should be closed during maintenance or emergency situations;

4. Export manual shut-off valve: The channel for manually closing the LPG output must be in the open position during operation, usually closed during maintenance or emergency situations;

6. Safety valve: In the event of an abnormal increase in LPG pressure inside the steel cylinder, when the pressure reaches 2.5 MPa, in order to prevent further pressure rise and dangerous situations, the safety valve will open and discharge the gaseous part of LPG to the outside. When the pressure reaches 2.3 MPa, the safety valve will close.

7. Overcurrent protection valve: When the LPG outflow speed exceeds the normal range due to pipeline rupture, joint leakage, or other reasons, the overcurrent protection valve will close the LPG output pipeline to prevent a large amount of LPG from flowing out.

Popular articles

-

How the CNG Automotive S

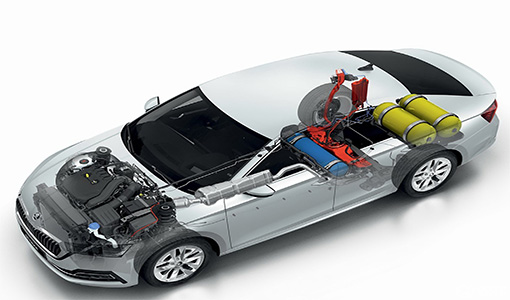

Compressed natural gas (CNG) automotive systems

-

What Is CNG Pressure Red

The pressure reducer of natural gas vehicle is

-

Advantages Of CNG Gas V

Compressed natural gas vehicles are vehicles th

-

Reasons For High Gas Con

1. Original vehicle condition A. The tec

-

Differences Between Sing

Characteristics of Gas Single Point Device

-

How To Improve The Power

1. Install ignition advance angle What i

-

Advantages And Principle

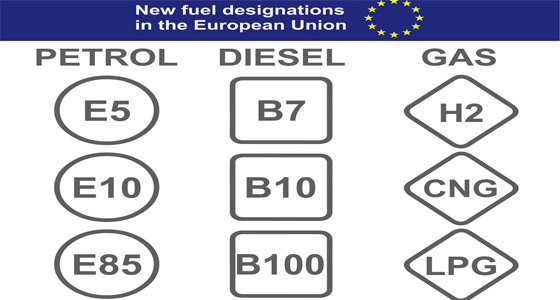

LPG and CNG are two mainstream alternati

-

How The CNG Gas Vehicle

If you want to know ¨C how does the CNG conversi

Latest comments

0piece comment

no comments, welcome to comment¡£