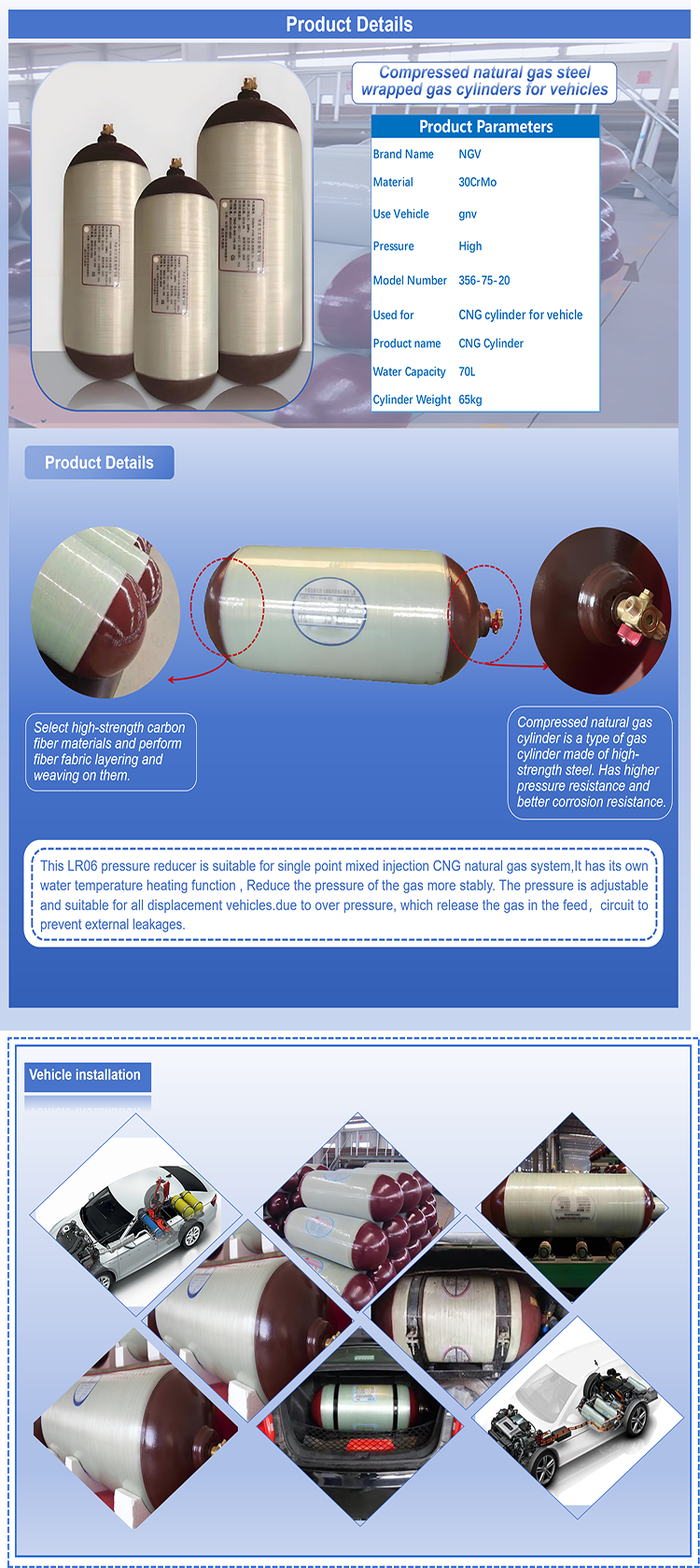

—— Introduction to compressed natural gas wrapped steel cylinders

Compressed natural gas cylinder is a type of gas cylinder made of high-strength steel. Compared to steel inner

liner wrapped gas cylinders, compressed natural gas steel cylinders have higher pressure bearing capacity and

better corrosion resistance.The manufacturing process of compressed natural gas cylinders is relatively simple,

but it requires strict adherence to a series of manufacturing standards and testing requirements. The main

manufacturing steps include the following aspects: first, selecting high-strength steel and performing corresponding

cutting and forming. Then, anti-corrosion treatment such as rust removal and painting should be carried out on the

surface of the steel. Through a series of process steps such as cold drawing, hydraulic forming, and overall welding

using CNC equipment, a complete compressed natural gas cylinder is ultimately formed.

There are certain differences in the process between steel inner liner wrapped gas cylinders and compressed natural

gas steel cylinders, mainly reflected in material selection and processing technology. The steel inner liner wrapped gas

cylinder is made of carbon fiber material, which has the advantages of lightweight and high strength, and is suitable

for use in the automotive field with high lightweight requirements. Compressed natural gas cylinders, on the other hand,

are made of steel and have higher pressure resistance and better corrosion resistance, making them suitable for general

automotive and commercial vehicle applications.

Different series offer different discounted prices. For more information, please contact us.