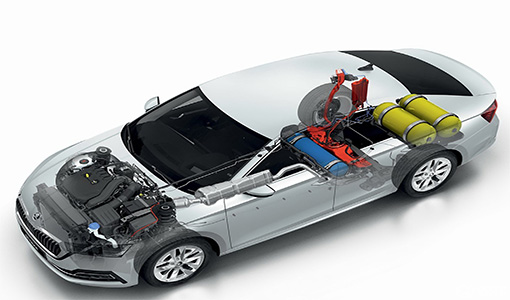

How To Choose The Correct CNG Vehicle Power Improvement Method?

Poor idle speed is one of the most common faults in electronically controlled fuel injection engines, which has various manifestations, including unstable idle speed, idle stalling, poor cold idle speed, and poor hot idle speed. There are many reasons for poor idle speed, often caused by a combination of several reasons. The fault involves a wide range of aspects and is difficult to repair. In the process of troubleshooting, the cause of the fault should be analyzed based on its specific manifestation. The following introduces several different forms of fault diagnosis and troubleshooting methods for poor idle speed.

Fault phenomenon

The engine starts normally, but whether it is cold or hot, the idle speed is unstable, and the idle speed is too low, making it easy to stall.

Fault cause

1. Air leakage in the intake system or vacuum system.

2. The air filter is blocked.

3. The idle control valve or additional air valve is not working properly.

4. The air flow meter is faulty.

5. The EGR valve is stuck open and cannot be closed.

6. Improper idle adjustment.

7. The oil circuit pressure is too low.

8. Poor atomization, oil leakage, or blockage of the fuel injector.

9. Poor spark plug.

10. High voltage line leakage or open circuit.

11. Misalignment of ignition timing.

12. The cylinder compression pressure is too low.

Trouble shooting

1. perform a self diagnosis of the fault and check for any fault codes. If so, search for the cause of the fault according to the displayed fault code. Special attention should be paid to whether there are faults in sensors and actuators that can affect idle operation, such as coolant temperature sensors, throttle position sensors, idle control valves, etc.

2. Check for air leaks in the intake system's pipe joints, vacuum hoses, exhaust gas recirculation system, and fuel vapor recovery system.

3. Check if the idle control valve is working properly. For pulse solenoid type idle control valves, the idle control valve wiring plug can be unplugged during engine operation. If the engine speed does not change, it indicates a malfunction in the idle control valve or control circuit. The circuit should be repaired or the idle control valve should be replaced.

4. When idling, unplug the high-pressure wires of each cylinder one by one and check whether the decrease in engine speed is equal. If the engine speed remains basically unchanged when unplugging the high voltage wire of a certain cylinder, it indicates that the cylinder is not working properly or is not working. The spark plug or fuel injector of the cylinder should be checked for faults, and the fuel injector control circuit should be checked for short circuits.

5. Check for high-voltage sparks. If the spark is too weak, the ignition system should be checked.

6. Disassemble and inspect the spark plugs of each cylinder, check for excessive wear or carbon buildup on the electrodes, and ensure that the spark plug electrode gap is normal.

7. Check the high voltage lines of each cylinder. If there are leakage points or signs of breakdown on the surface of the high voltage lines, or use a multimeter to measure the resistance of the high voltage lines. If the resistance is greater than 25k, it indicates that the high voltage lines are damaged and should be replaced.

8. Check the fuel pressure. The fuel pressure should be around 250kPa at idle speed. If the fuel pressure is too low, check the oil pressure regulator, electric fuel pump, and fuel filter.

9. Adjust the engine idle speed according to the prescribed procedure.

10. Check the air flow meter.

11. Carefully listen to the working sound of each cylinder's fuel injector at idle speed. If the working sound of the fuel injectors in each cylinder is uneven, it indicates that the fuel injectors in each cylinder are not evenly sprayed, and the fuel injectors should be dismantled, cleaned, or replaced.

12. Check the cylinder compression pressure. If the pressure is below 0.8MPa, the engine should be disassembled and inspected.

13. Check and adjust the valve clearance.

If the above checks are normal, the fuel injectors of each cylinder can be disassembled for inspection and cleaning. If a certain fuel injector is found to have poor atomization or oil leakage, and cannot return to normal after cleaning, the fuel injector should be replaced. Finally, check the engine computer.

Refer to£ºhttps://www.evoautogas.com/increase-cng-car-pickup/

Refer to£ºhttps://www.evoautogas.com/increase-cng-car-pickup/

The pictures and articles are from the internet. If there is any infringement, please contact us to delete them.

Popular articles

-

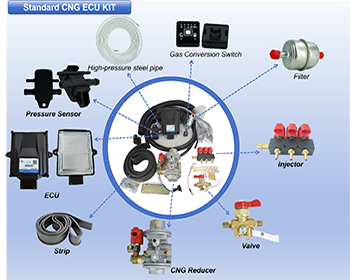

How the CNG Automotive S

Compressed natural gas (CNG) automotive systems

-

What Is CNG Pressure Red

The pressure reducer of natural gas vehicle is

-

Advantages Of CNG Gas V

Compressed natural gas vehicles are vehicles th

-

Reasons For High Gas Con

1. Original vehicle condition A. The tec

-

Differences Between Sing

Characteristics of Gas Single Point Device

-

How To Improve The Power

1. Install ignition advance angle What i

-

Advantages And Principle

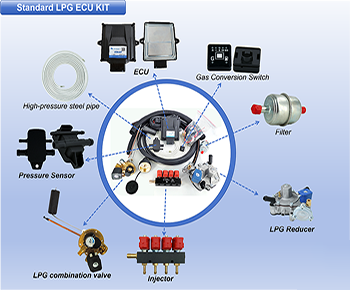

LPG and CNG are two mainstream alternati

-

How The CNG Gas Vehicle

If you want to know ¨C how does the CNG conversi

Latest comments

0piece comment

no comments, welcome to comment¡£