Introduction To High-speed Gas Common Rail Injector

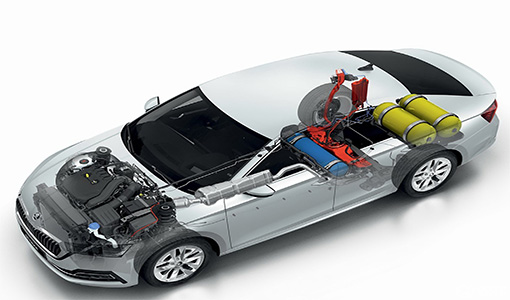

One of the most critical devices in the electronic control injection system of gas fuel engines is the gas injector, whose performance directly affects the quality of fuel injection and thus the performance of the engine. To facilitate the installation of gas vehicles, multiple gas injectors are usually fixed on a unified gas distribution rack. At this time, we refer to the gas injector as the gas common rail injector, abbreviated as the gas injector or the gas common rail. The biggest difference between gas injectors and gasoline injectors is that they require a larger flow cross-section to ensure the passing capacity of atmospheric flow; In addition, unlike liquid fuels, which have certain lubrication and sealing effects, their normal service life is a serious challenge faced by gas injectors. The fuel rail is a component in the direct injection gas kit that injects air into the intake branch pipe, including three cylinders and four cylinders. It plays an important role in the entire gas system. The fuel rail is connected to the computer board through a wire harness, and is adjusted by computer calculation to command the fuel supply to the engine. The pressure and gas consumption of natural gas are controlled by the computer and fuel rail.

According to the working conditions of the engine, the requirements for gas fuel injectors generally include the following:

1. The appropriate gas supply pressure mainly depends on engine compression ratio, displacement and speed, as well as injection timing.

2. The gas flow rate and corresponding flow characteristics that meet the requirements of engine power, economy, and emissions.

3. Suitable coil voltage and power of the solenoid valve.

4. The valve body switch has short response time and good dynamic response characteristics.

5. Good safety, reliability, and durability.

Spray rail features and usage:

Small size, compact structure, and high control accuracy.

The noise is minimal, and the detachable part has a simple structure, making it very convenient for daily maintenance.

The substrate is made of high-quality aviation aluminum material, which is processed and formed as a whole after heat treatment, making it more durable and corrosion-resistant.

It can perfectly replace all spray rails with a resistance of 3 ¦¸ on the market, and the interface is the same as the commonly used rail spray common rail on the market.

The electrical system and internal wiring are packaged as a whole at once, resulting in higher reliability.

Applicable model: Vehicles with a displacement of 1.0~3.0 are universal (standard nozzle aperture of 1.6mm). Large displacement models need to expand their holes according to the actual situation.

Refer to:https://www.bosch-mobility.com/en/solutions/valves/cng-injector/

Refer to:https://www.bosch-mobility.com/en/solutions/valves/cng-injector/

The pictures and articles are from the internet. If there is any infringement, please contact us to delete them.

Popular articles

-

How the CNG Automotive S

Compressed natural gas (CNG) automotive systems

-

What Is CNG Pressure Red

The pressure reducer of natural gas vehicle is

-

Advantages Of CNG Gas V

Compressed natural gas vehicles are vehicles th

-

Reasons For High Gas Con

1. Original vehicle condition A. The tec

-

Differences Between Sing

Characteristics of Gas Single Point Device

-

How To Improve The Power

1. Install ignition advance angle What i

-

Advantages And Principle

LPG and CNG are two mainstream alternati

-

How The CNG Gas Vehicle

If you want to know ¨C how does the CNG conversi

Latest comments

0piece comment

no comments, welcome to comment¡£