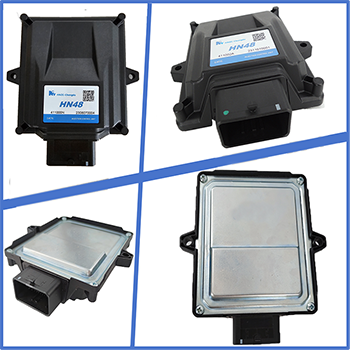

Introduction to HN48 Dual Purpose Fuel Controller

Product Introduction

The HN48 dual fuel controller is a newly developed dual fuel control unit suitable for both post market and foreign trade markets by our company. It collects and processes signals from the gasoline controller system and achieves fuel gas conversion of the vehicle through flexible intervention. The HN48 dual fuel controller supports four cylinder independent ignition control function and four cylinder oil gas conversion function. By adjusting the wiring harness, 6-cylinder and 8-cylinder control can also be achieved.

Applicable scope

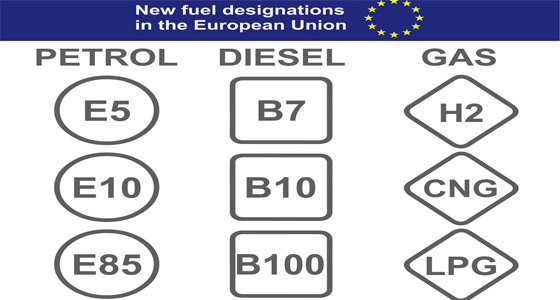

Suitable for dual fuel (gasoline, natural gas) naturally aspirated models.

Main features

• Four cylinder independent ignition

• Support for leak detectors

• Fault diagnosis function

• Support CAN bus and gasoline ECU communication function

• 48PIN automotive grade connector

• Protection level IP67

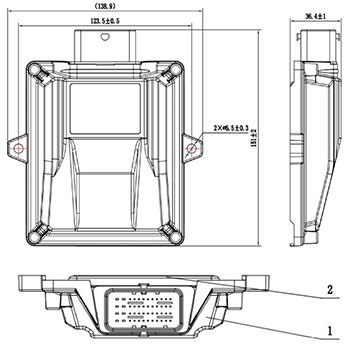

• Size: 152 * 139 * 37mm

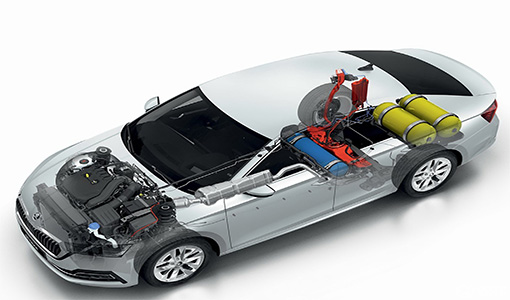

Shell Overview

The shell of the controller consists of two parts: the upper shell material is PA6GF30, and the lower shell material is Galvanized steel plate and assembled with silicone sealing, with no sharp burrs or edges on the surface of the shell.

As shown in the figure:

Installation requirements

The controller is installed on the entire vehicle. In order to ensure its normal and reliable operation, the installation and usage requirements are explained as follows:

Working environment temperature requirements

(1) The temperature range of the operating environment is -40 ¡æ to+105 ¡æ, and cooling should be used if the temperature exceeds the range;

(2) Pay attention to placing the controller in a position with good air flow;

(3) Avoid drastic changes in temperature;

(4) Avoid scaling on the surface of the controller (mud, dust, air pollution, etc.), otherwise it may cause heat dissipation energy force damage.

Installation position requirements

(1) The ventilation is good, and it is strictly prohibited to have covers on the controller to avoid scaling caused by long-term use;

(2) Stay away from heat sources (such as exhaust pipes) to avoid thermal radiation to the controller; Avoid direct heat flow generated by heat sources acting on the controller;

(3) Stay away from high-frequency and high-energy sources;

(4) During installation, it is advisable to choose a relatively high and dry location to avoid dampness, water immersion, splashing of mud and water, and impact of sand and stones; Avoid contact with corrosive liquids;

(5) The wiring harness near the controller should be fixed and reliable to prevent vibration waves caused by instability from reaching the controller;

(6) Prevent installation in locations with high vibrations;

(7) Ensure electromagnetic shielding;

(8) Consider installing protective covers, radiators, and other devices as appropriate;

(9) The selection of installation location should be based on the convenience of loading, unloading and maintenance.

Installation direction requirements

(1) Try to use an installation method with an appropriate inclination angle on the upper part to prevent water from being trapped on the surface;

(2) The wiring harness should preferably be connected from the side;

(3) It is not allowed to connect the wiring harness through the upper part of the controller.

Fault analysis and troubleshooting

The controller will continuously monitor the circuit storage related to the gas alarm, gas nozzle, and gasoline ECU Pool voltage and so on, as well as the controller itself, and perform credibility checks on sensor output signals, actuator drive signals, and internal signals. When the vehicle's engine system malfunctions, the following methods should be followed for handling:

Turn the key switch to the ON position and use a diagnostic tool to read the fault information in the controller for judgment Specific faults, and check the relevant sensors and actuators. If the fault cannot be eliminated, please record the fault information and pass it on to NGV's after-sales service engineer.

Storage and transportation

During transportation, the controller should be handled with care and avoid excessive accumulation of packaging boxes to avoid damage

Controller.The controller should be stored in a cool, dry, and dust-free environment, and the controller must not be exposed exposed to liquid dirt.

Receiving and Inspection

The recipient should check each packaging box to confirm that the label, part number, and required supply of zero are on the packaging box

Is the part number consistent. If damage is found, it must be reported to the relevant departments of NGV in a timely manner.

Inspection content:

a) Check if the label of the controller complies with regulations;

b) Check if there is obvious physical damage to the outer shell of the controller;

c) Check the connector housing and terminals of the controller for physical damage.

After sales service

Conduct matters in accordance with the terms of the quality assurance agreement signed between the customer and NGV.

Popular articles

-

How the CNG Automotive S

Compressed natural gas (CNG) automotive systems

-

What Is CNG Pressure Red

The pressure reducer of natural gas vehicle is

-

Advantages Of CNG Gas V

Compressed natural gas vehicles are vehicles th

-

Reasons For High Gas Con

1. Original vehicle condition A. The tec

-

Differences Between Sing

Characteristics of Gas Single Point Device

-

How To Improve The Power

1. Install ignition advance angle What i

-

Advantages And Principle

LPG and CNG are two mainstream alternati

-

How The CNG Gas Vehicle

If you want to know ¨C how does the CNG conversi

Latest comments

0piece comment

no comments, welcome to comment¡£