Experimental Study On The Effect Of High-pressure Methane Jet On Laminar Flams

The natural cylinder direct injection technology is beneficial for improving engine efficiency and reducing harmful emissions. It is currently an important technical means for natural gas internal combustion engines and has become a research hotspot and frontier. The natural gas jet has a significant impact on the combustion inside the cylinder. A natural gas engine with direct injection in the cylinder, whether it is diesel ignition or spark ignition, will form a premixed flame, and then the natural gas will jet into the cylinder at high speed and burn under the action of the premixed flame. In order to study the effect of natural gas direct injection flow on premixed flames, the author established a constant volume combustion bomb optical testing bench, using methane as gas fuel and igniting the methane jet with an ignition needle. The ignition characteristics of the methane jet were tested under different injection delay conditions to study the effect of methane jet on premixed laminar flames.

1.Test equipment and methods

The experiment uses methane as the gas fuel and adopts spark ignition method. Figure 1 is a schematic diagram of the visualization test system, where the distance from the nozzle to the ignition pin is 40 mm. The visualization test system mainly includes: constant volume combustion bomb, optical schlieren system, and gas supply system. The constant volume combustion bomb uses quartz glass as the optical channel of the high-speed camera at both ends, and light can enter the high-speed camera after reflection through the viewing window. The detailed test methods and parameters can be found in reference [1].

2.Test results and analysis

2.1 Effect of premixed settling time on premixed laminar flames

Figure 2 shows the comparison of flame propagation distances for different premixed settling times. The relationship between the propagation distance of all flames and time is linear, indicating that combustion is a spherical development and a laminar flame. At the same time, as the pre mixed settling time continues to increase, the influence of the pre mixed settling time on the propagation distance of the pre mixed laminar flame becomes smaller and smaller. Due to delayed methane injection during the experiment ¦Ó The maximum is 3.0 ms, and as of 5.0 ms, the premixed settling time is greater than 0.8 s, and the flame propagation distance remains basically unchanged. Therefore, in order to maintain consistency in the development of premixed laminar flames, the author chose a premixed resting time of 0.8 seconds.

2.2 Impact of jet timing on premixed laminar flames

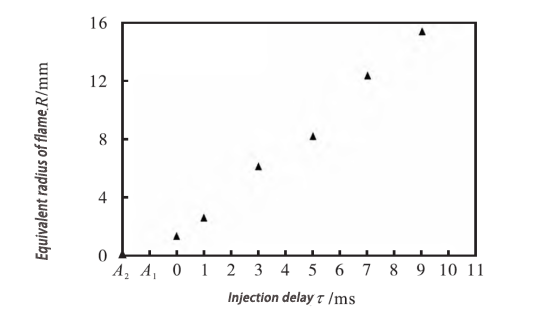

Figure 3 shows different injection delays ¦Ó The variation of the equivalent radius R of the lower premixed laminar flame. It can be seen that as the injection delay increases, the premixed laminar flame R increases linearly. This is because the injection delay becomes longer, and the time for the development of the premixed laminar flame is more sufficient, resulting in an increase in the equivalent radius. At the same time, when the injection time is at the ignition time£¨ ¦Ó Before A2 ms, even during the duration of the jet pulse, ignition failed to form a laminar flame, and the jet could not be ignited. The premixed laminar flame R was 0. It indicates that there must be a jet delay in order to form a premixed laminar flame and further ignite the jet.

2.3 Impact of jet delay on flame development

2.3.1 Changes in flame propagation distance

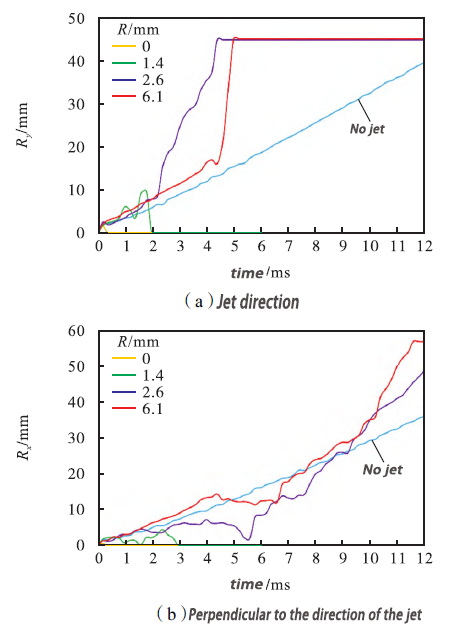

Figure 4 shows the comparison of flame propagation distances under different R. When the premixed laminar flame R=0mm, sparks occur during methane injection, but no flame is formed. Therefore, Ry and Rx both momentarily increase and then sharply decrease to 0. When the premixed laminar flame R=1.4 mm occurs simultaneously with injection and ignition, the laminar flame appears and Ry slowly increases. The jet impingement ignites the premixed flame, disrupting the stability of the premixed laminar flame. Ry shows a brief fluctuation, and after the flame extinguishes, Ry quickly becomes 0, and the trend of Rx is consistent with Ry. When the premixed laminar flame R=2.6 mm, Ry and Rx slowly increase without the presence of a jet, and the trend is similar to that of a pure premixed flame; Subsequently, Ry rapidly increased, while Rx initially remained unchanged and then gradually decreased (close to 0), ultimately increasing sharply again. At this stage, the premixed ignition flame extinguishes, causing Rx to gradually decrease, while the jet is ignited, causing a sudden increase in Ry and a rapid increase in Rx. When the jet causes the premixed laminar flame to extinguish, the current premixed laminar flame R is the critical flame radius R0, which is R0=2.6 mm. When the premixed laminar flame R=6.1 mm, Rx and Ry first increase linearly. After the jet is ignited, Ry increases sharply, and Rx slightly decreases and remains stable, As the jet continues, the flame coverage area of jet combustion rapidly increases, leading to a continued increase in Rx. At this point, laminar combustion coexists with turbulent combustion. After the jet is ignited, turbulent combustion gradually dominates.

2.3.2 Changes in flame propagation speed

Figure 5 shows the comparison of flame propagation speed under different R. It can be seen that when the premixed laminar flame R=0 mm, due to the simultaneous occurrence of ignition and injection, ignition occurs within the jet pulse width. After the ignition spark appears, the premixed ignition flame cannot be formed, and vy and vx first become negative values, and then become 0. When the premixed laminar flame R=1.4 mm, due to the small radius and low flame intensity of the premixed laminar flame, after the jet appears, the premixed laminar flame is blown out by the jet, and both vy and vx show a brief increase and quickly become negative values, ultimately tending towards 0. Due to the influence of high-speed jets, the trend of variation in vy is more intense compared to vx. When the premixed laminar flame R=2.6 mm, before the formation of turbulent combustion, the methane jet drives the premixed laminar flame forward, and vy has been in a fluctuating and increasing state. After the jet is ignited to form turbulent combustion, the peak value of vy is about 13 m/s. During the forward development of the jet, due to the entrainment of the jet, vx gradually decreases to a negative value, and then as the jet burns, vx gradually increases and remains at around 7 m/s. When the premixed laminar flame R=6.1 mm, due to the high stability of the premixed laminar flame, after the jet passes through the flame, vy first remains unchanged at 3 m/s. After the jet combustion begins, vy rapidly increases to 18 m/s. In the laminar combustion stage, vx remains stable at 3 m/s, and then the jet appears, breaking the boundary of the laminar combustion flame, gradually reducing to a negative value. When laminar combustion transforms into turbulent combustion, vx rapidly increases to 13 m/s.

3.Conclusion

(1) The delay of methane injection determines the development of premixed laminar flames, manifested by different R values of premixed laminar flames; The larger the R, the higher the intensity of the premixed laminar flame.

(2) As the pre mixed laminar flame R increases, the stability of the laminar flame is higher and it is not easy to blow out. The methane jet is more easily ignited by the pre mixed laminar flame, forming turbulent combustion.

(3) There exists a critical equivalent radius R0, where the premixed laminar flame is blown out by the jet, but the premixed laminar flame successfully ignites the jet, and the jet successfully ignites, forming turbulent combustion; When R is greater than the critical value R0, the methane jet is more likely to be ignited by the premixed laminar flame. At the same time, the premixed laminar flame remains a laminar flame in the undisturbed area of the jet. At this time, laminar flames and turbulent combustion flames coexist, and the flame propagation speed increases.

Refer to:

Refer to:

[1] Lei Yan, Ding Mengzhu, Qiu Tao, et al. Experimental study on the effect of high-pressure methane jet on laminar flames [J]. Journal of Internal Combustion Engines, 2022, (02): 113-118

https://www.sciencedirect.com/science/article/abs/pii/S0360544220328024

The pictures and articles are from the internet. If there is any infringement, please contact us to delete them.

Popular articles

-

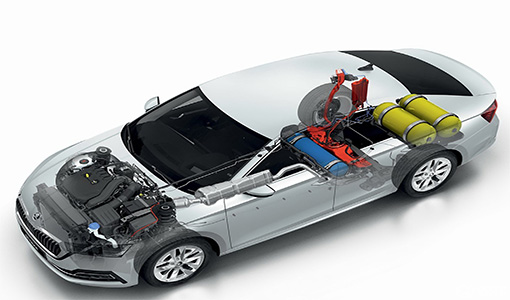

How the CNG Automotive S

Compressed natural gas (CNG) automotive systems

-

What Is CNG Pressure Red

The pressure reducer of natural gas vehicle is

-

Advantages Of CNG Gas V

Compressed natural gas vehicles are vehicles th

-

Reasons For High Gas Con

1. Original vehicle condition A. The tec

-

Differences Between Sing

Characteristics of Gas Single Point Device

-

How To Improve The Power

1. Install ignition advance angle What i

-

Advantages And Principle

LPG and CNG are two mainstream alternati

-

How The CNG Gas Vehicle

If you want to know ¨C how does the CNG conversi

Latest comments

0piece comment

no comments, welcome to comment¡£